Laser/

Welding

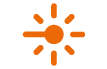

Since 2019 EUROMODEL has introduced diode and CO2 laser welding technology in its catalog: the most innovative and flexible machinery that we provide at your disposal.

In recent years, laser welding of thermoplastic materials has increasingly taken hold in the world of industrial applications that require rapid processes, good aesthetics, and thin welding profiles. Welds performed with diode and Co2 lasers add to traditional welding methods such as ultrasound, vibration, or hot blade welding. It provides all the advantages of non-contact welding, without forming filaments or burrs but the possibility of welding complex geometries. It also offers significant advantages and performance capabilities such as: precision, cleanliness, aesthetics, speed, and repetitiveness compared to traditional plastic welding methods.

Laser Welding

Machinery

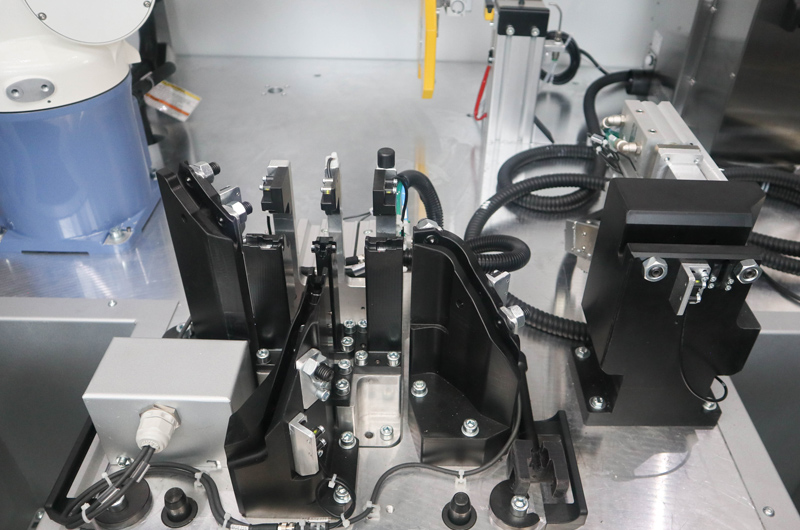

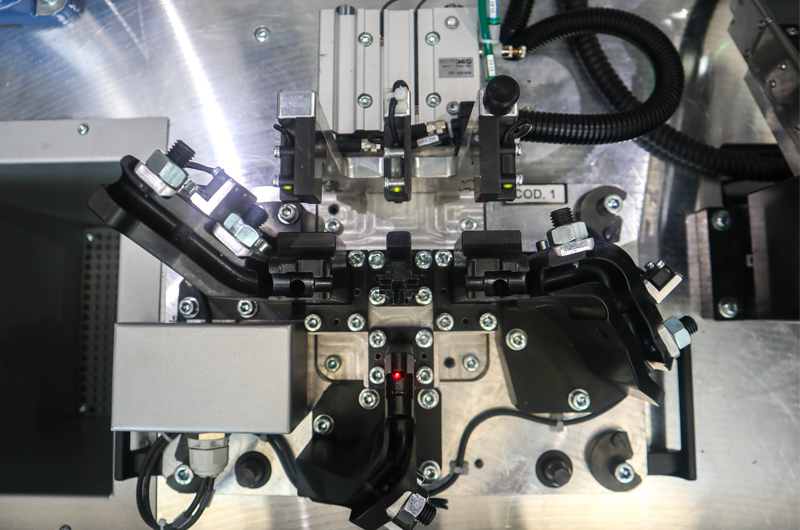

We offer solutions specially designed to meet our customer needs:

- Electrical Machines: our machines perfectly integrate Co2 and diode welding systems based on specific requests. We combine decades of experience in automation with the most innovative laser welding technologies

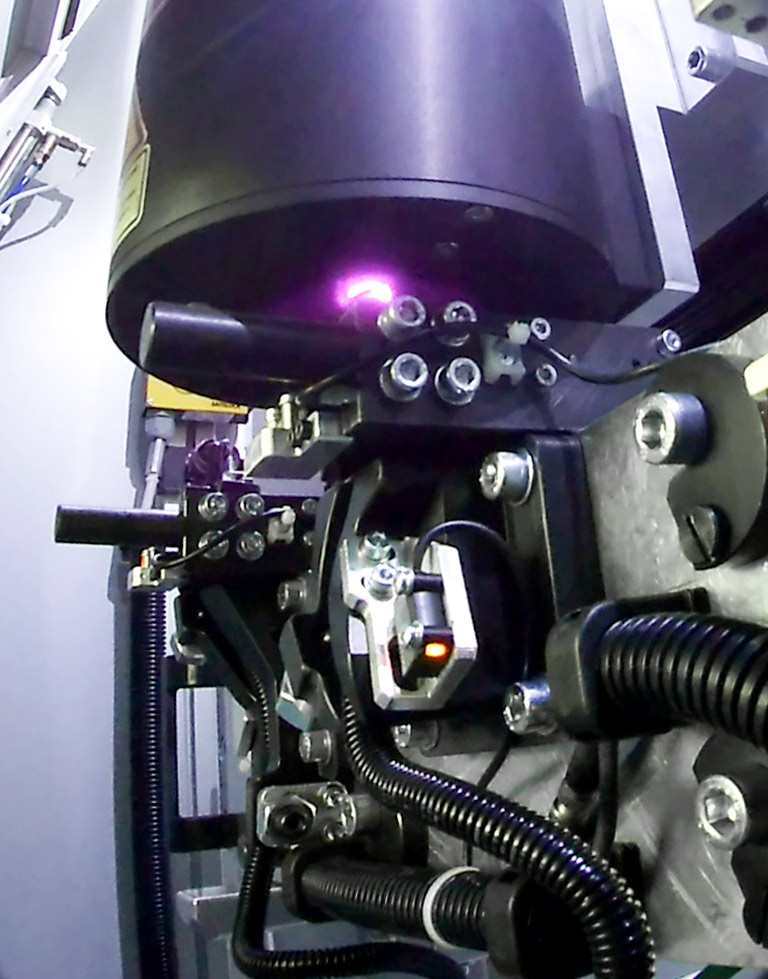

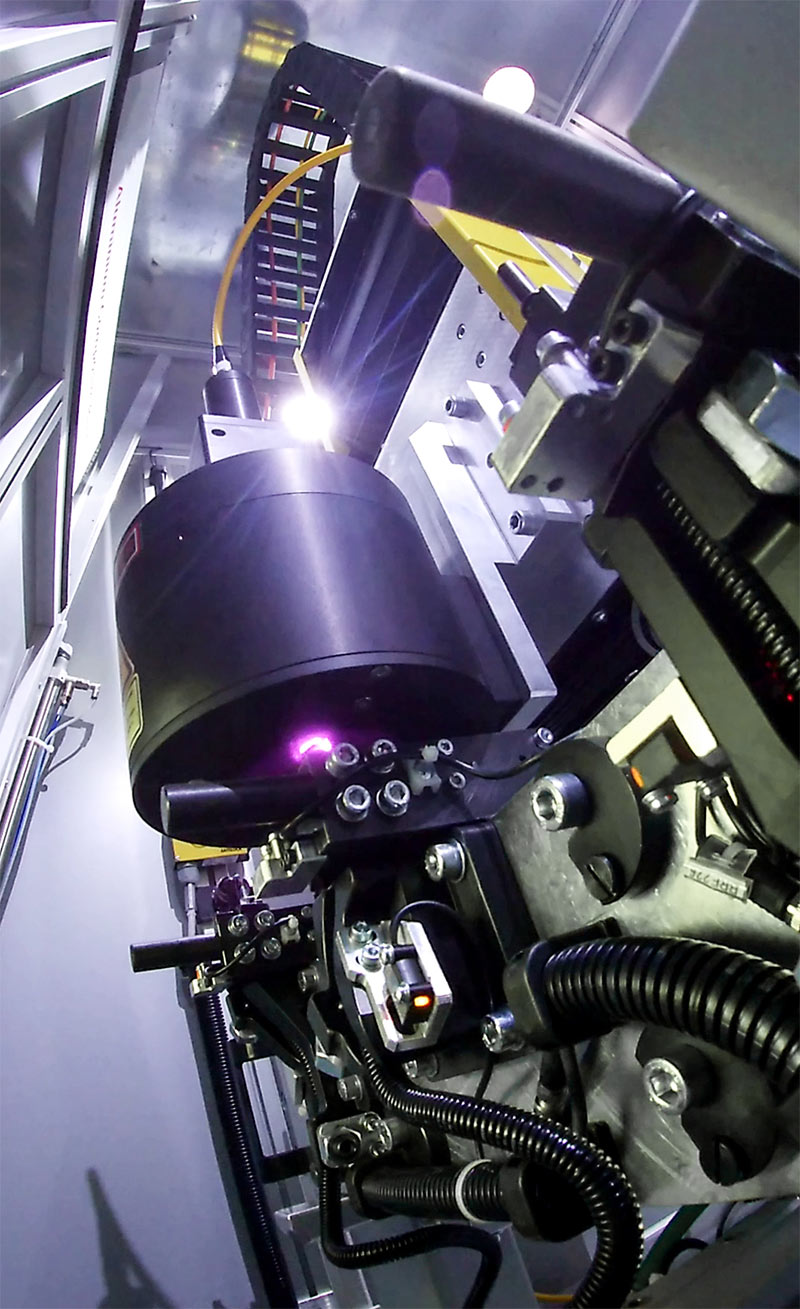

- Automated Solutions: they are the most flexible and configurable. Thanks to the use of anthropomorphic robots, we are able to develop individual machines that can be used for multiple products. Thanks to the compact welding heads we can weld in the most complex areas.

- Laser-proof Booths: The new standard cabin with integrated operator panel combines design with functionality. Designed to be in compliance with regulation, it allows viewing the welding cycle through the inspection area.

- All welding data (times, temperatures, pressure, and penetration) can be stored and associated with the QR / bar code and interfaced with the factory traceability system.

Tools/equipment

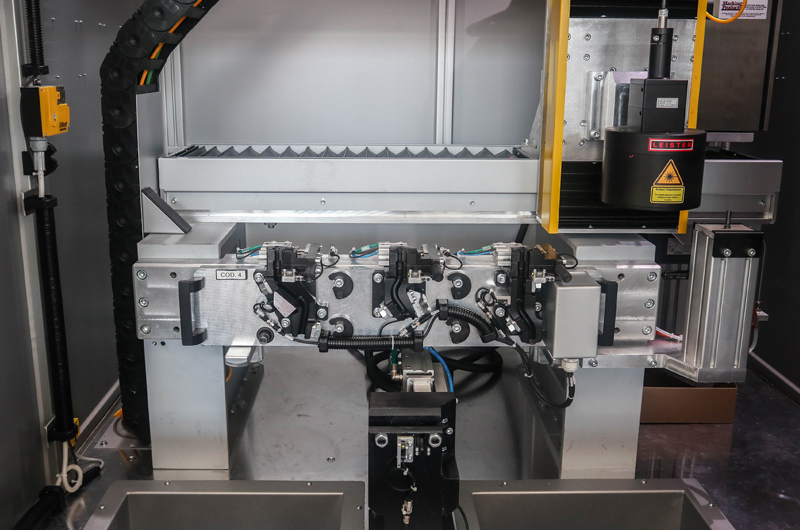

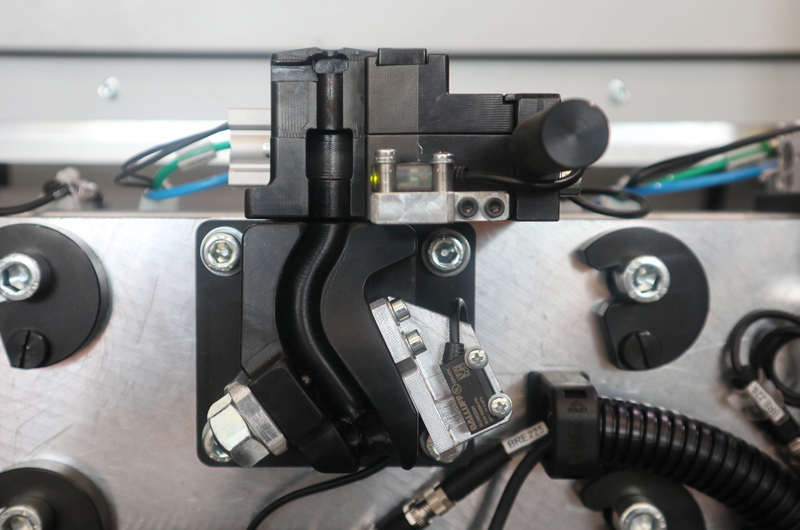

The main feature of our system is that only the compact welding head extends into the processing area

Anthropomorphic robots can be equipped with our compact welding head which extends the work area inside to allow welding of products with complex geometries

We are able to integrate the most common welding technologies available on the market thanks to the flexibility of our machines

Joined Parts

Minimum heat supply inside components

- No mechanical stress on the components

- Aesthetically pleasing – the surface of the material has a clean appearance with no visible burrs

- The laser has excellent flexibility on the joining profiles

- Wide range of weldable materials