Fuel Tanks/

Finishing

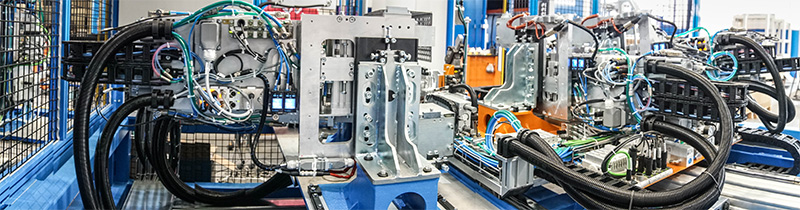

The processing lines of the fuel tanks are among the largest and most complex machinery that EUROMODEL is able to create. All our experience at your disposal.

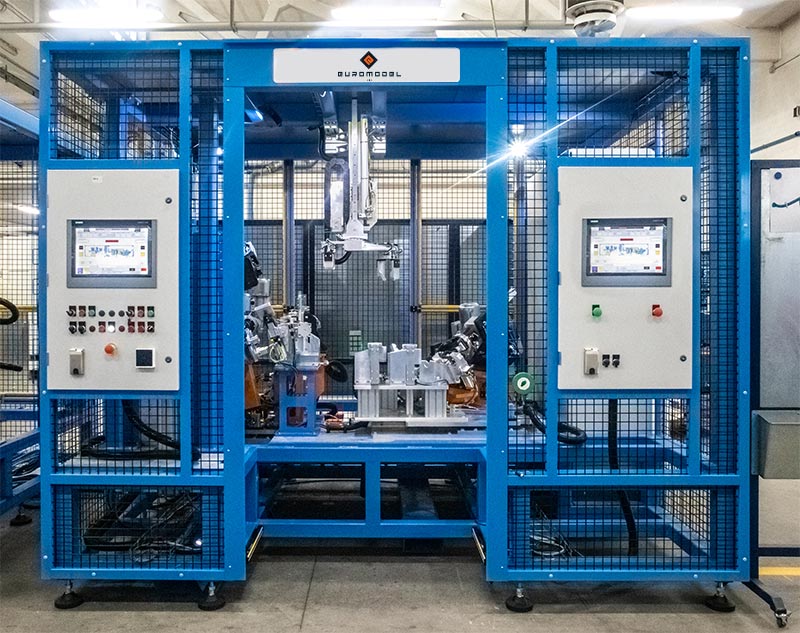

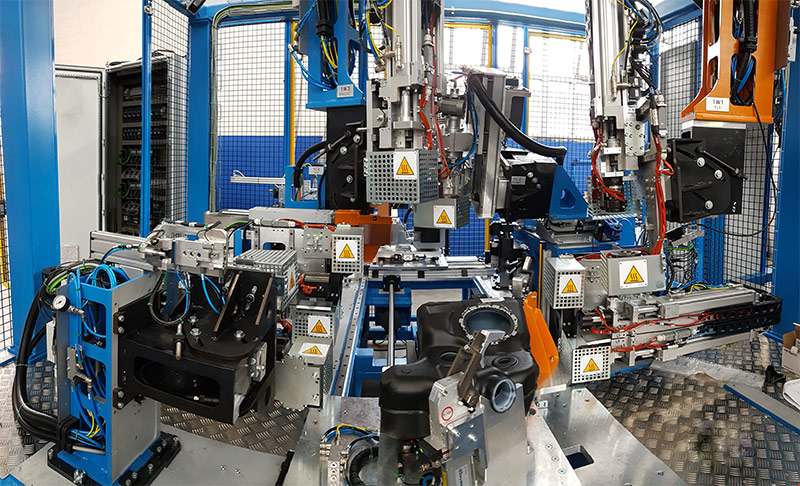

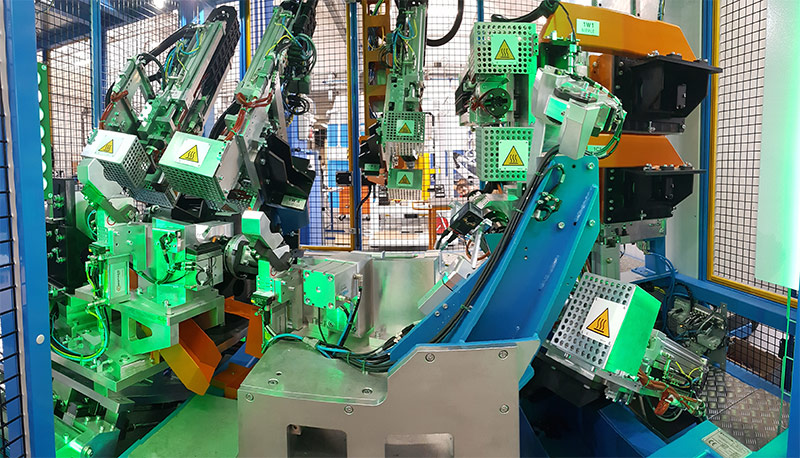

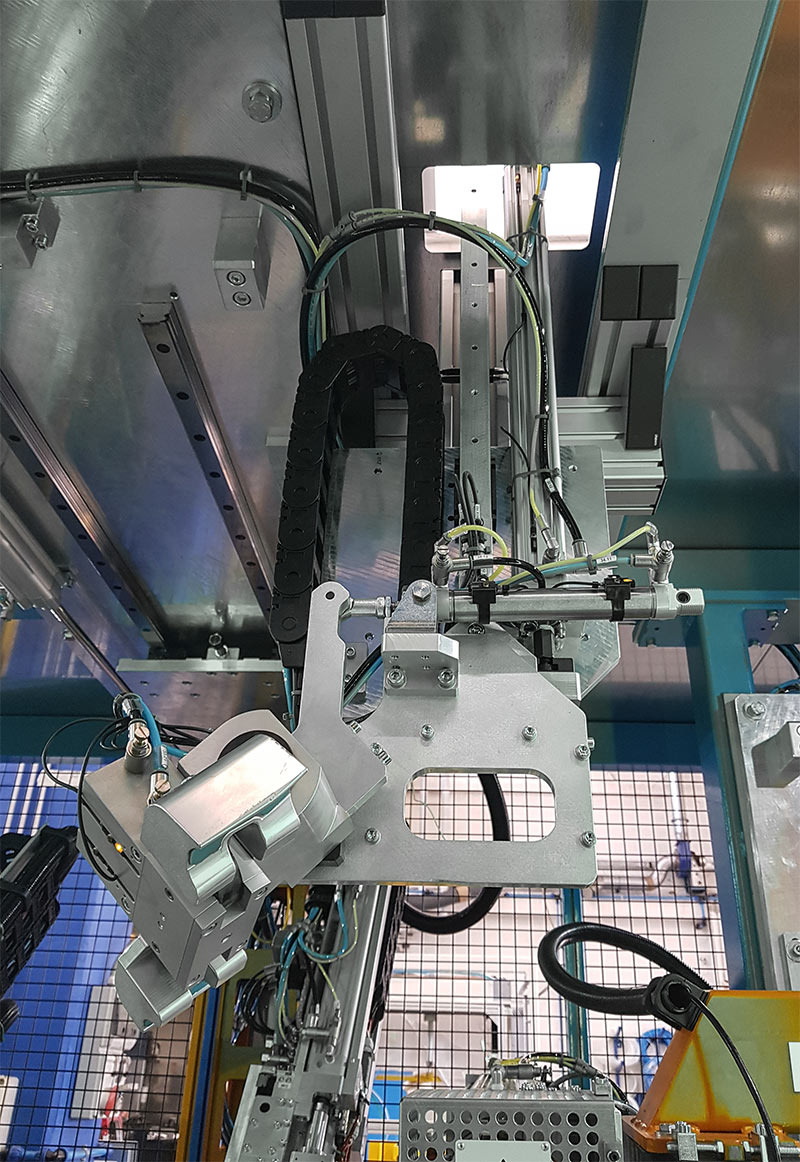

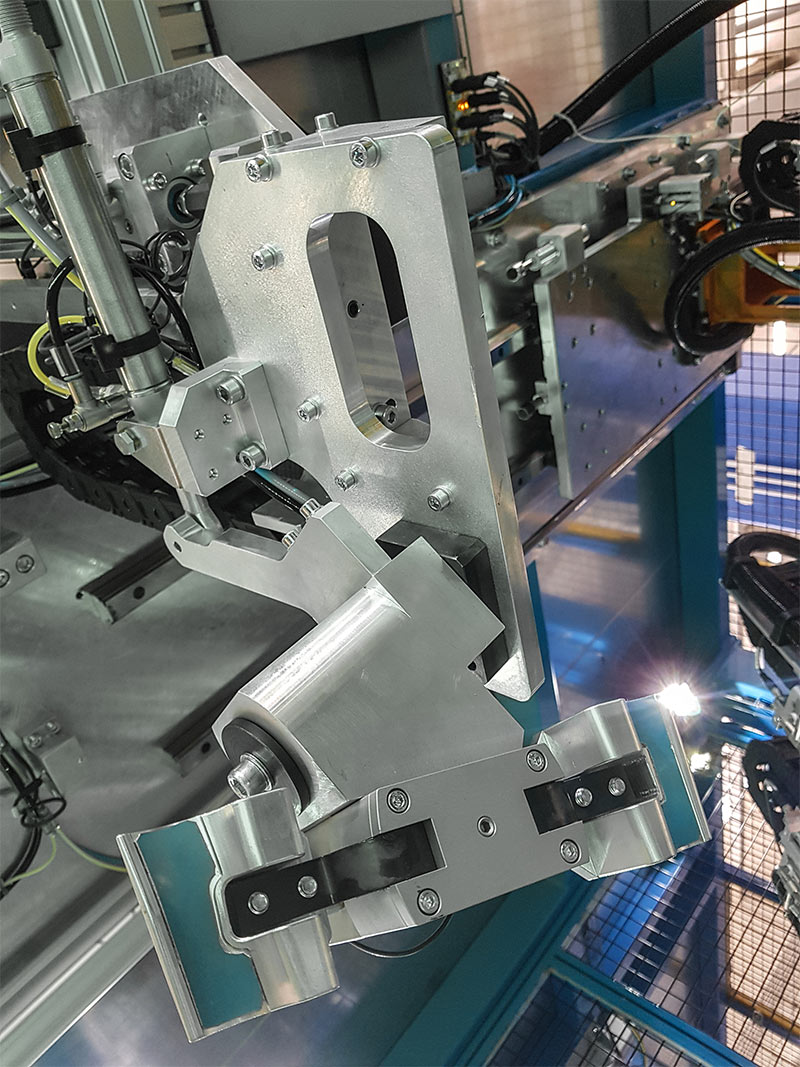

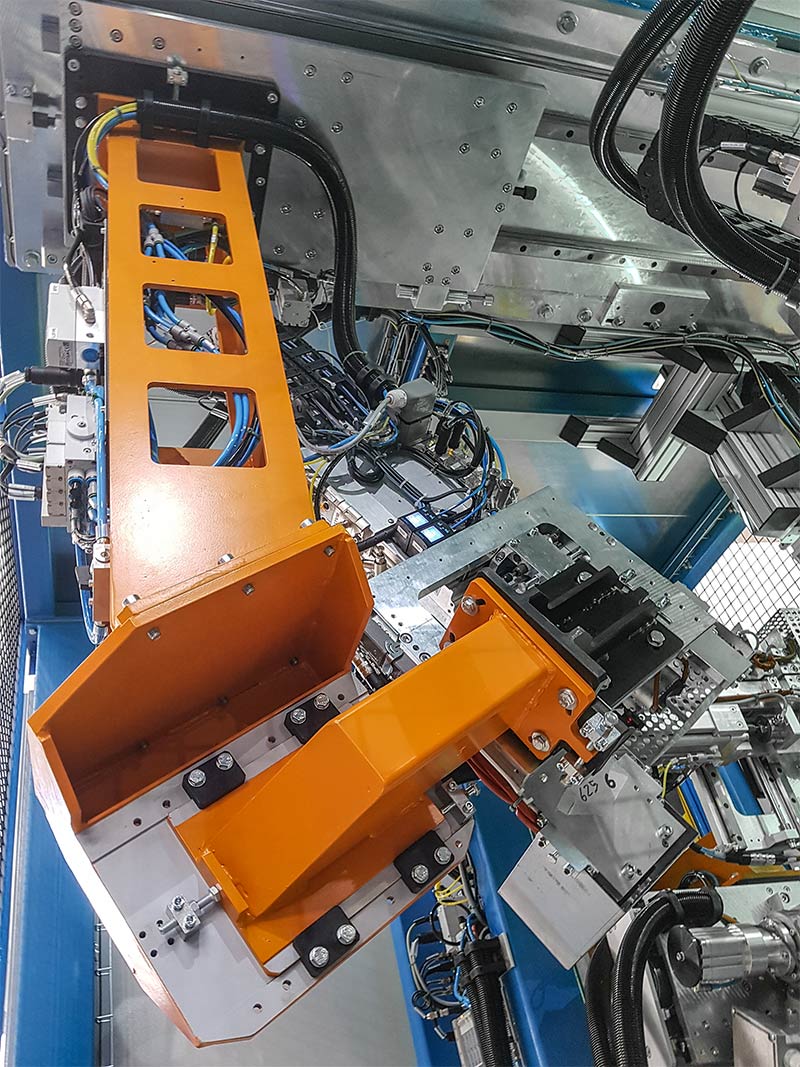

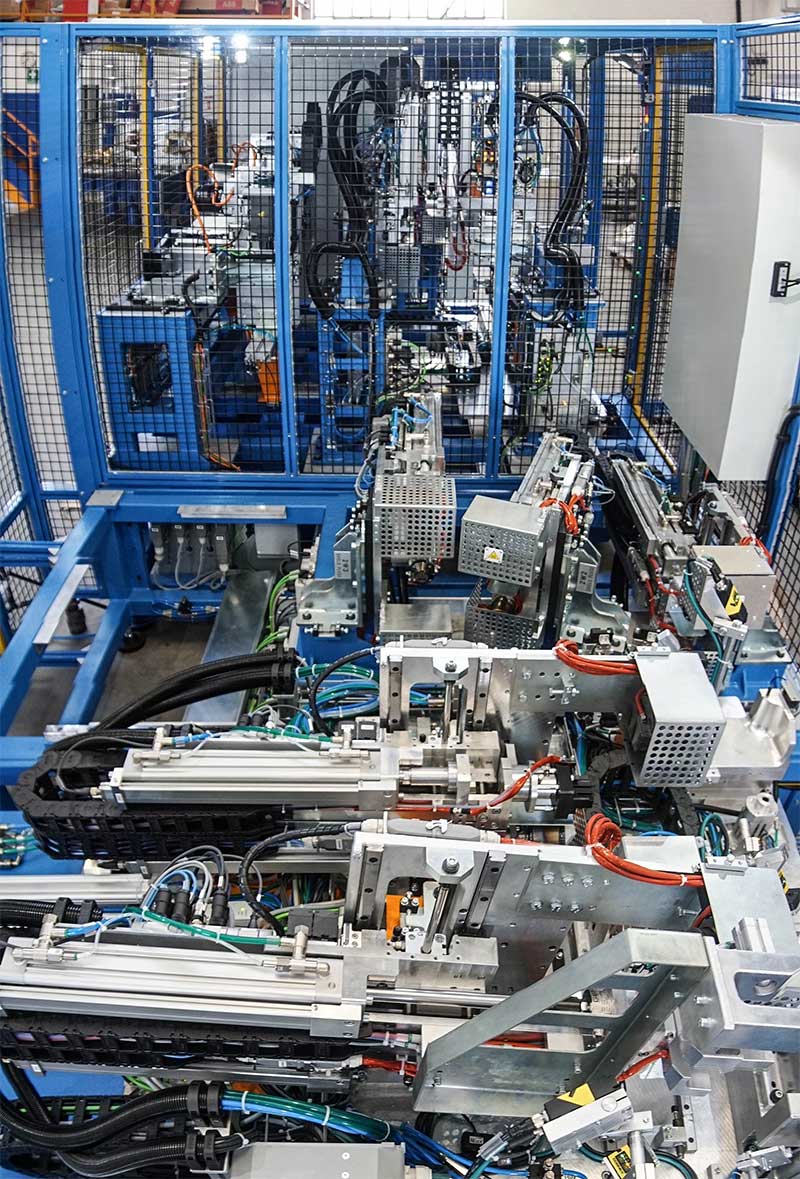

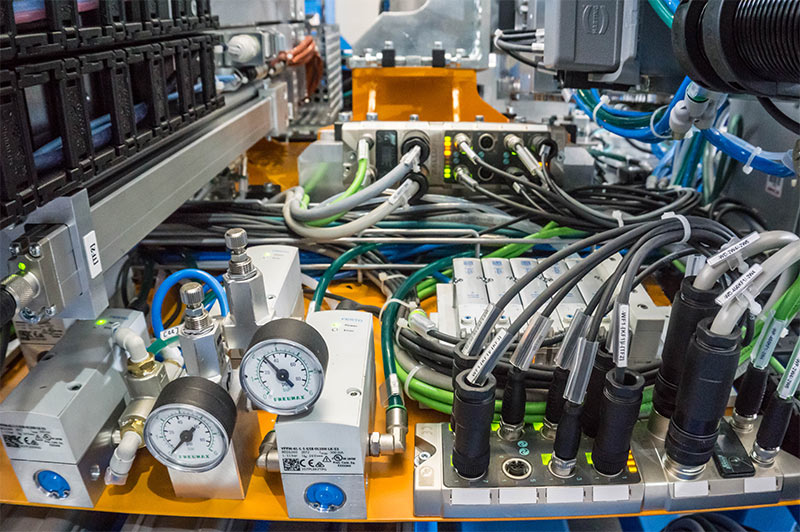

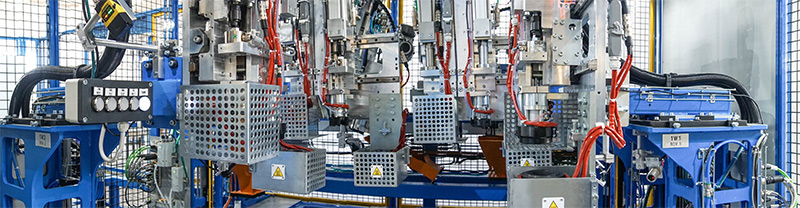

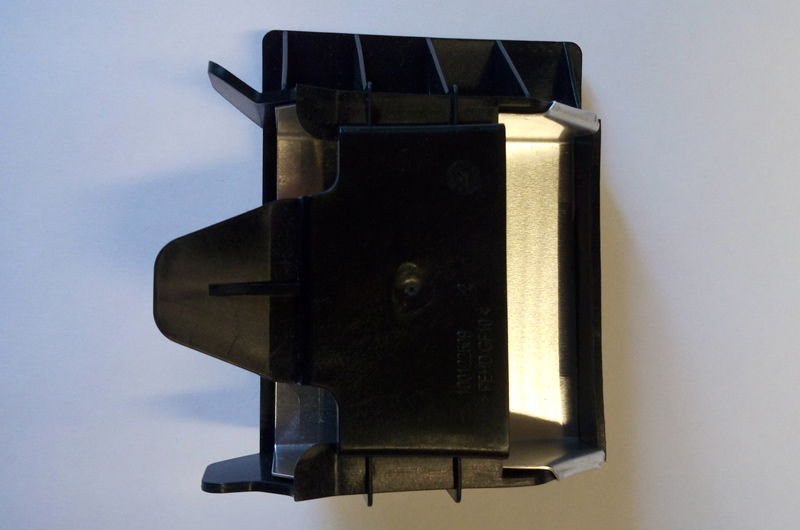

The fuel tanks, made via blow molding, are subsequently processed, and tested in different automated cutting, welding, and processing stations through a series of auxiliary operations to obtain a finished component. And so are the Filler Pipes. This process takes place simultaneously in the various processing stations of our machinery specially made according to the needs of our customers. The Urea Tanks, i.e. relating to the SCR system, used to adapt Diesel engines to European standards are obtained by joining two injected half-bodies where the components are welded on in advance. In both cases, the standard drilling and welding units can be mounted in a fixed or mobile position, possibly robotic, in order to work on different models, minimizing the necessary adjustments.

Fuel Tank Welding

Machinary

The various configurations proposed are:

- Fuel tanks and Filler Pipes: construction of process lines or robotic production lines, equipped with cutting and welding units, vision and control systems, automatic mechanized systems for component assembly, etc.…

- SCR Tanks – component welding: machines with fixed welding units or with frames with interchangeable units. Possibility of robotic loading / unloading of the bearing half-shells and components.

- SCR Tanks – bearing half-shells welding: use of EUROMODEL standard hot plate welding machines, with electrical motion controls and the possibility to install a feeding turntable

- All Welding Data (times, temperatures, pressure, and penetration) can be stored and associated with the QR / bar code and interfaced with the factory traceability system.

Tools/equipment

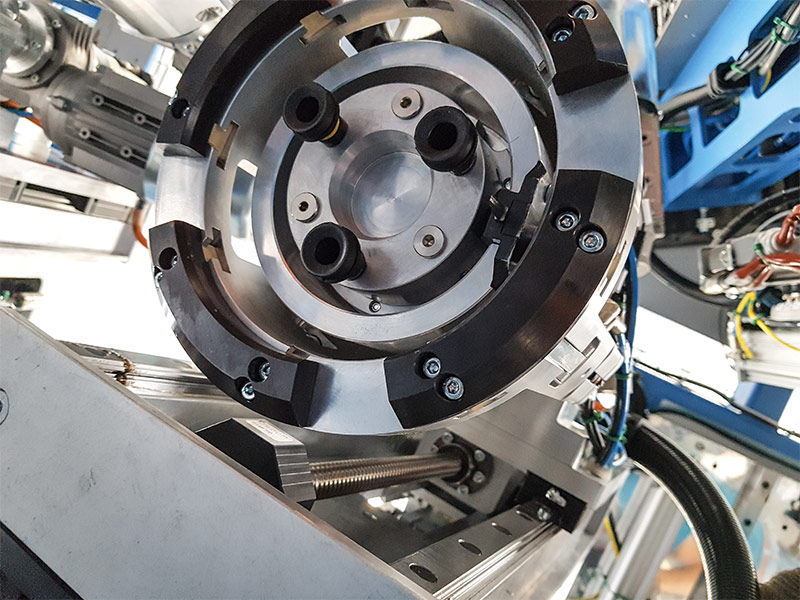

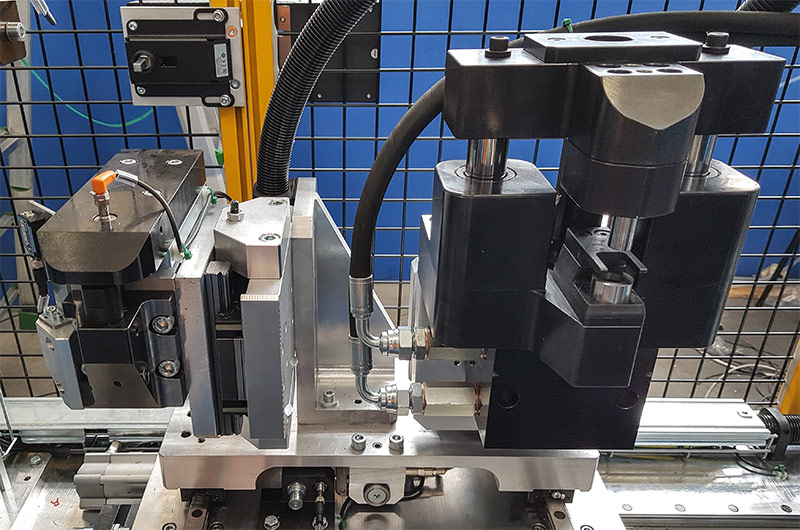

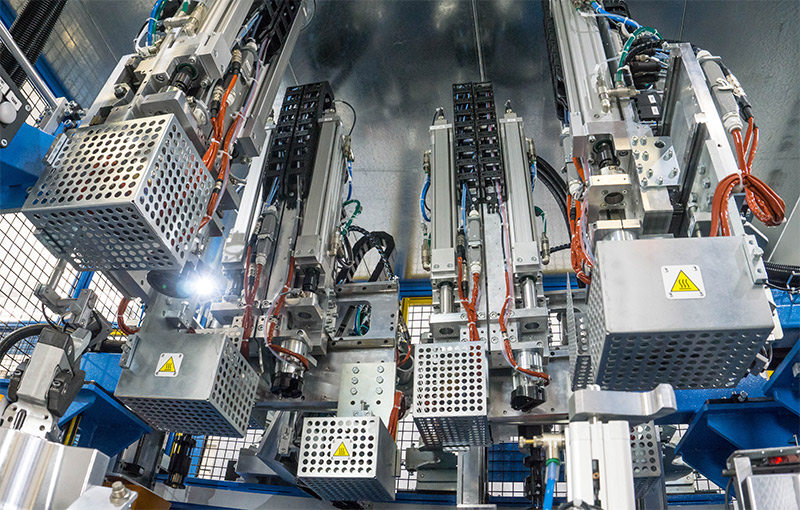

Standard drilling unit without swarf with adjustable drilling diameter

· Processing and punching unit for the fuel pump seat

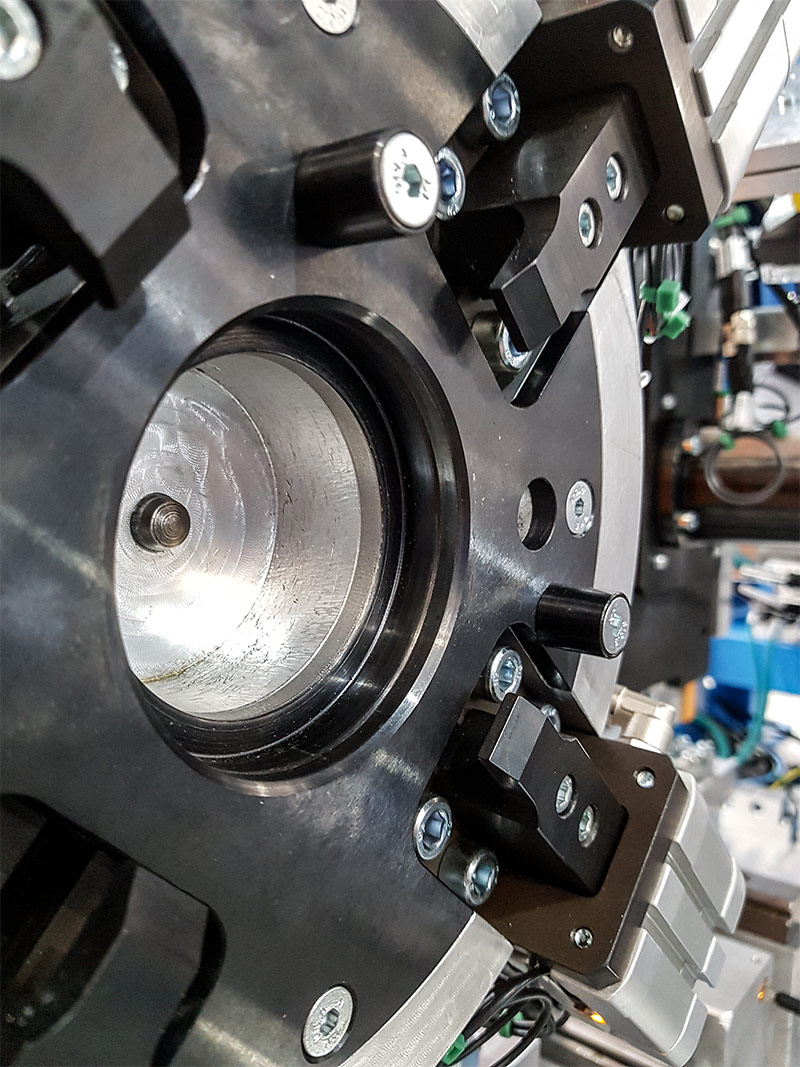

· Standard welding unit with separate temperature control for component and tank, compensation of the geometric tolerances of the tank, control of the forces, times and depth of the welds specially designed for multi-layer tanks

· Standard pump screwing unit, with torque and angle control

· Automatic mechanized systems for component assembly

· Vision and control systems

Joined Parts

- Both blown or PP and HDPE injected tanks can be welded. Significant differences in geometric and dimensional tolerances can be absorbed without affecting the mechanical strength and watertight feature of the weld.

- We are able to guarantee all the manufacturing processes necessary to obtain a signature product.